Product Categories

- Electric Motor (42)

- Marine Electric Motor (40)

- Industrial Motor (2)

- Hydraulic Motor (77)

- Control System (25)

Voltage: AC380/400/415/440/480/660V

Frequency: 50Hz / 60Hz

Protection level: IP22/IP23/IP44/IP56

Ambient temperature: -25℃ ~45℃

XMS91 Series Marine Anchor Windlass Control Box is suitable for starting, braking, turning or reversing, and changing speed control of various types of electric ship anchorage and cable winch AC motors. The XMS91 series marine anchor windlass control box is suitable for three-phase AC 50H in, 60Hz, 380V, 400V, 415V, 440V, 480V, and 660V. It is used to control the three-phase asynchronous motor of an AC crane variable speed for the startup, brake, turn, reverse, shift and protection of equipment such as anchorage, anchorage winch or anchorage combination.

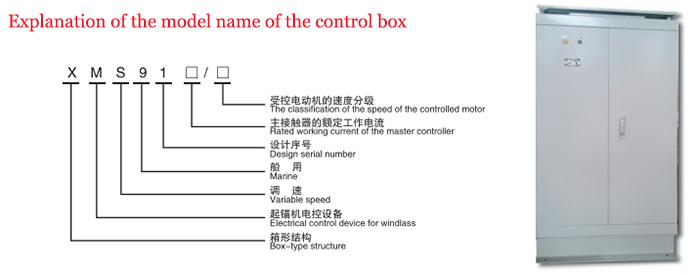

Explanation of the model name of the control box

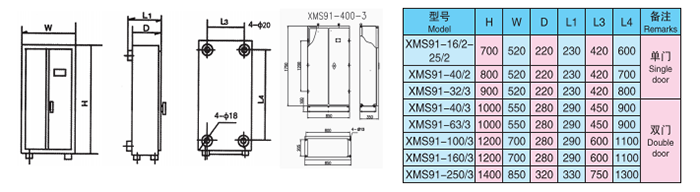

Outline installation dimension

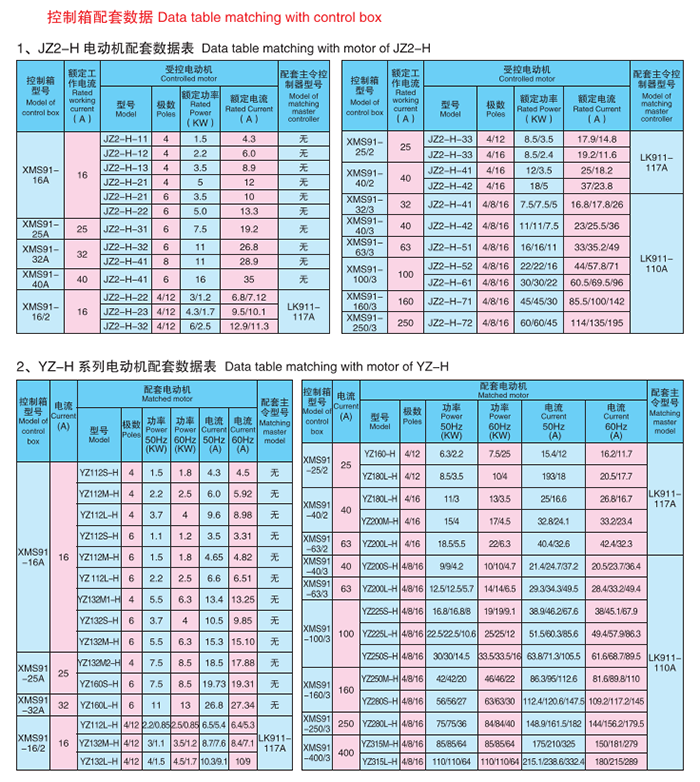

Data table matching with control box

This series of control boxes are protective and are rated IP 22, IP 23, IP 44, and IP 56. The case housing is made of high-quality steel plate pressing welding, the box body is vertical, front door, according to different specifications, the single or double door. The electrical components are placed in the box and mounted directly on the rear bottom plate made of thick steel plates. The bottom plate and the upper and lower ends of the box are fixed by two fastening screws, and the upper and lower screws are released to remove the case for easy repair.

The bottom of the box is equipped with a wiring hole and wiring terminal row, and the inside of the door is equipped with a wiring electrical schematic diagram. When installing or overhauling, follow the schematic to connect the power and control cables to the corresponding symbolic positions in the terminal row. There are four mounting holes on the rear bottom plate of the case to secure the control box to the vertical wall.